Description

Successful Complete Project

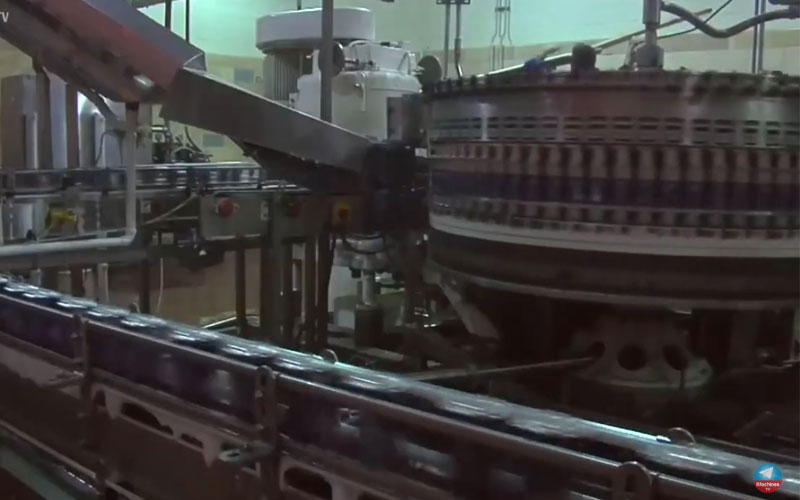

The installation of the Krones Can Line at Pepsi in Setif, Algeria, was successfully completed in 2015. The project aimed to establish a high-capacity production line capable of processing 40,000 cans per hour, ensuring efficiency and quality.

- High-performance canning line with a capacity of 40,000 cans per hour.

- Seamless integration with existing factory systems for enhanced productivity.

- Compliance with international industrial standards and safety regulations.